In recent years, sustainability has become an essential focus across multiple industries, including the production of household and commercial bathroom products. A Sanitary Ware Manufacturer plays a significant role in shaping how environmentally responsible products are designed, produced, and distributed. By integrating sustainable production processes into their operations, these manufacturers help reduce environmental impact while meeting the growing demand for reliable sanitary solutions.

A modern Sanitary Ware Manufacturer understands that resource management is at the heart of sustainable production. Raw materials such as clay, kaolin, and quartz are essential in sanitary ware manufacturing, and responsible sourcing is a priority. Many companies in this sector actively seek suppliers who follow ethical and environmentally sound extraction practices. By doing so, the Manufacturer ensures that its entire supply chain supports sustainability from start to finish.

Energy consumption is another area where a Sanitary Ware Manufacturer can make meaningful changes. The production of sanitary products often involves high-temperature kiln operations and energy-intensive shaping and glazing processes. To address this, manufacturers have started upgrading their equipment to energy-saving models and optimizing kiln schedules to reduce fuel usage. Some have also invested in renewable energy systems, further lowering their overall carbon footprint. This makes the Manufacturer a participant in global efforts to reduce industrial greenhouse gas emissions.

Water usage is an equally important aspect of sustainable production in this industry. A Sanitary Ware Manufacturer typically consumes significant amounts of water during shaping, glazing, and finishing processes. Modern facilities have adopted closed-loop water systems, which allow water to be treated and reused within the manufacturing process. This not only reduces waste but also decreases the strain on local water resources. As a result, the Manufacturer can reduce its environmental footprint while maintaining product quality and production capacity.

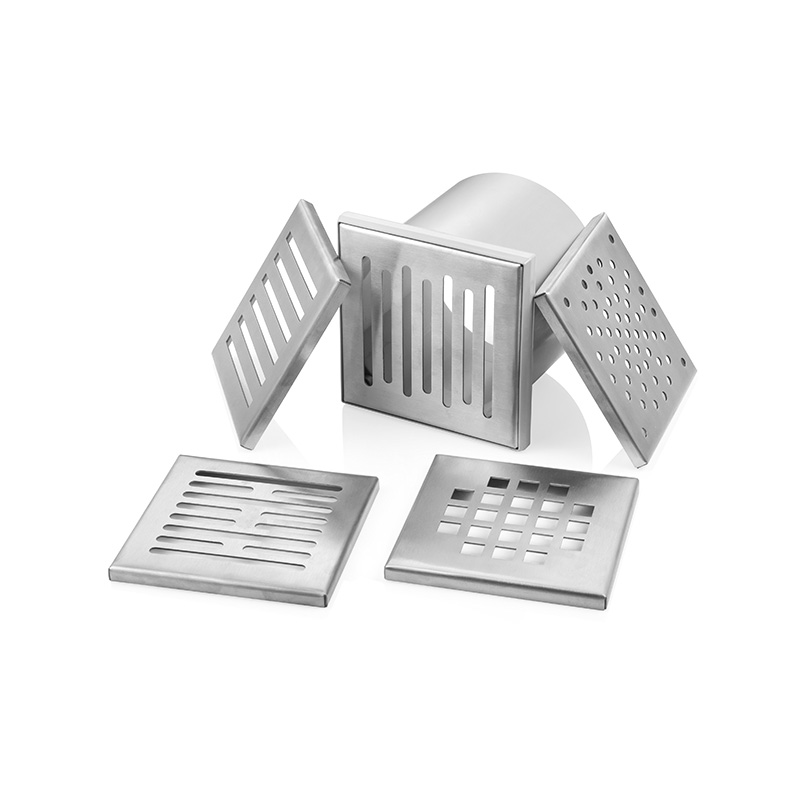

Waste management is another critical consideration for a Sanitary Ware Manufacturer pursuing sustainable production processes. Manufacturing sanitary ware generates various types of waste, including fired and unfired ceramic material, glaze overspray, and packaging debris. Many companies have adopted recycling systems that recover usable material from production waste. This recycled material is then reintegrated into the production cycle, reducing the need for new raw materials. Through effective waste management programs, a Manufacturer not only conserves resources but also limits landfill contributions.

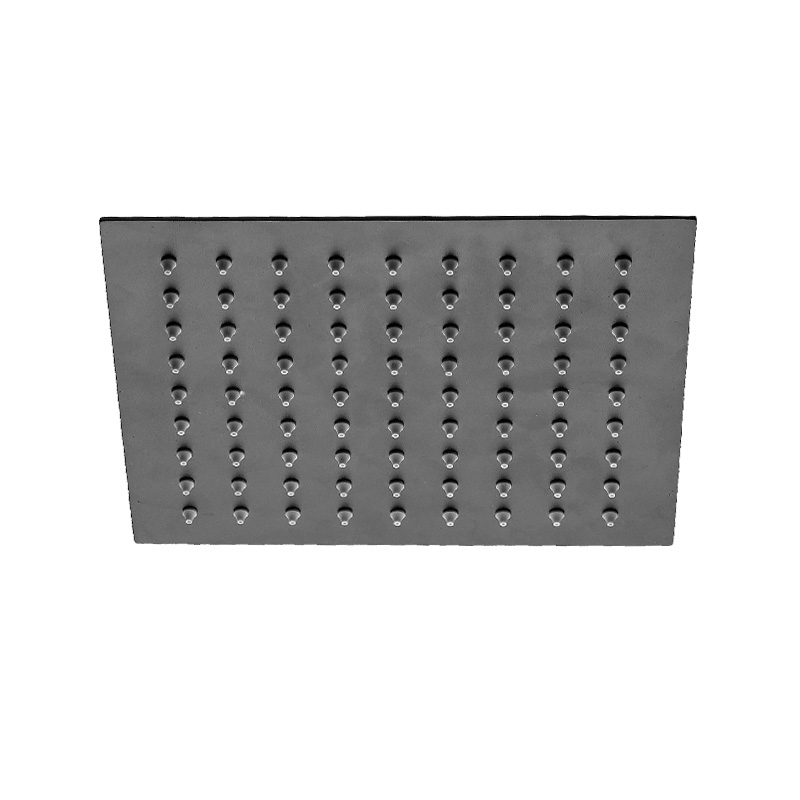

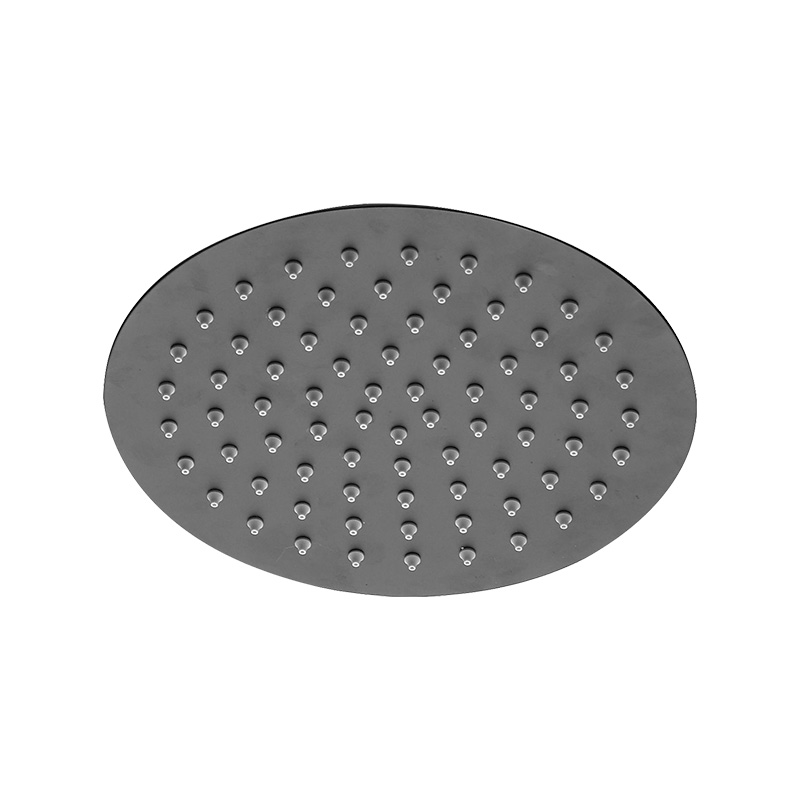

In addition to environmental efforts, a Sanitary Ware Manufacturer often incorporates sustainability into product design. Many modern sanitary ware products are developed with water-saving features such as dual-flush toilet systems and low-flow faucets. These products help consumers reduce their water usage, contributing to overall conservation efforts. By focusing on the lifecycle impact of their products, the Manufacturer can offer solutions that align with both environmental and customer expectations.

Sustainable packaging has also become an important part of operations for a Sanitary Ware Manufacturer. Traditional packaging materials such as plastic and foam have a significant environmental impact. To address this, manufacturers are increasingly turning to biodegradable or recyclable alternatives. Cartons made from recycled paper and protective materials derived from plant-based fibers are now commonly used, reducing waste and simplifying recycling for end-users.

Employee involvement is another area where a Sanitary Ware Manufacturer can strengthen its sustainable production processes. Many companies have established training programs and awareness campaigns to promote environmental responsibility within the workplace. Employees are encouraged to identify areas for improvement, suggest energy-saving practices, and participate in waste reduction initiatives. This collective effort ensures that sustainability is embedded within the organizational culture of the Sanitary Ware Manufacturer.

Partnerships and certifications are also valuable tools for a Sanitary Ware Manufacturer committed to sustainable practices. Collaborating with environmental organizations and participating in sustainability programs allows manufacturers to stay informed about new technologies and industry standards. Additionally, pursuing third-party certifications for environmental management and sustainable production demonstrates a company’s commitment to responsible manufacturing. These actions help a Sanitary Ware Manufacturer build trust with consumers and stakeholders who prioritize environmental values.

English

English 中文简体

中文简体 عربى

عربى Español

Español